How to Choose Bar and Section Mill Manufacturer for Your Steel Operation

Quick Answer: Choose bar and section mill manufacturer based on their engineering expertise, manufacturing quality, integration capabilities, and long-term support infrastructure. Look for manufacturers with decades of experience, proven worldwide installations, flexible modernization options (from component upgrades to complete systems), and comprehensive maintenance support. Established manufacturers like Darting, with over 50 years in the industry, offer the reliability and expertise needed for successful mill modernization.

Steel plant managers face a common problem. Their rolling mills are getting old. The equipment cannot meet modern production standards. Tolerances are not tight enough. Energy costs keep rising. Meanwhile, customers demand new products that old mills simply cannot make efficiently enough without complete replacement.

Choosing the right bar and section mill manufacturer is critical. Good manufacturers do more than sell equipment. They help you modernize your operation. Darting has worked with steel producers worldwide for over 50 years, bringing Taiwanese engineering quality and complete support to operations that need to evolve.

What Makes Modern Bar and Section Mill Technology Different?

Modern bar and section mills are completely different from equipment installed 15 years ago. Today’s systems use digital controls that manage every part of the rolling process with precision that older mills cannot match.

Digital Control and Energy Efficiency

Modern bar and section mills reach higher rolling speeds and hold tighter tolerances. Digital systems monitor everything in real-time. They adjust for temperature changes, compensate for material variations, and track wear patterns. Old mills relied on operator experience. New mills do this automatically. The results speak for themselves, consistent quality and lower scrap rates.

Production Flexibility

The biggest advantage is flexibility. Good manufacturers understand that modernization does not mean throwing away functional equipment. Darting provides everything from individual rolling mill stands to complete integrated lines. You can modernize in stages, addressing your biggest challenges first while expanding your product range to meet new customer requirements.

What Should You Look for in a Manufacturing Partner?

Engineering Expertise

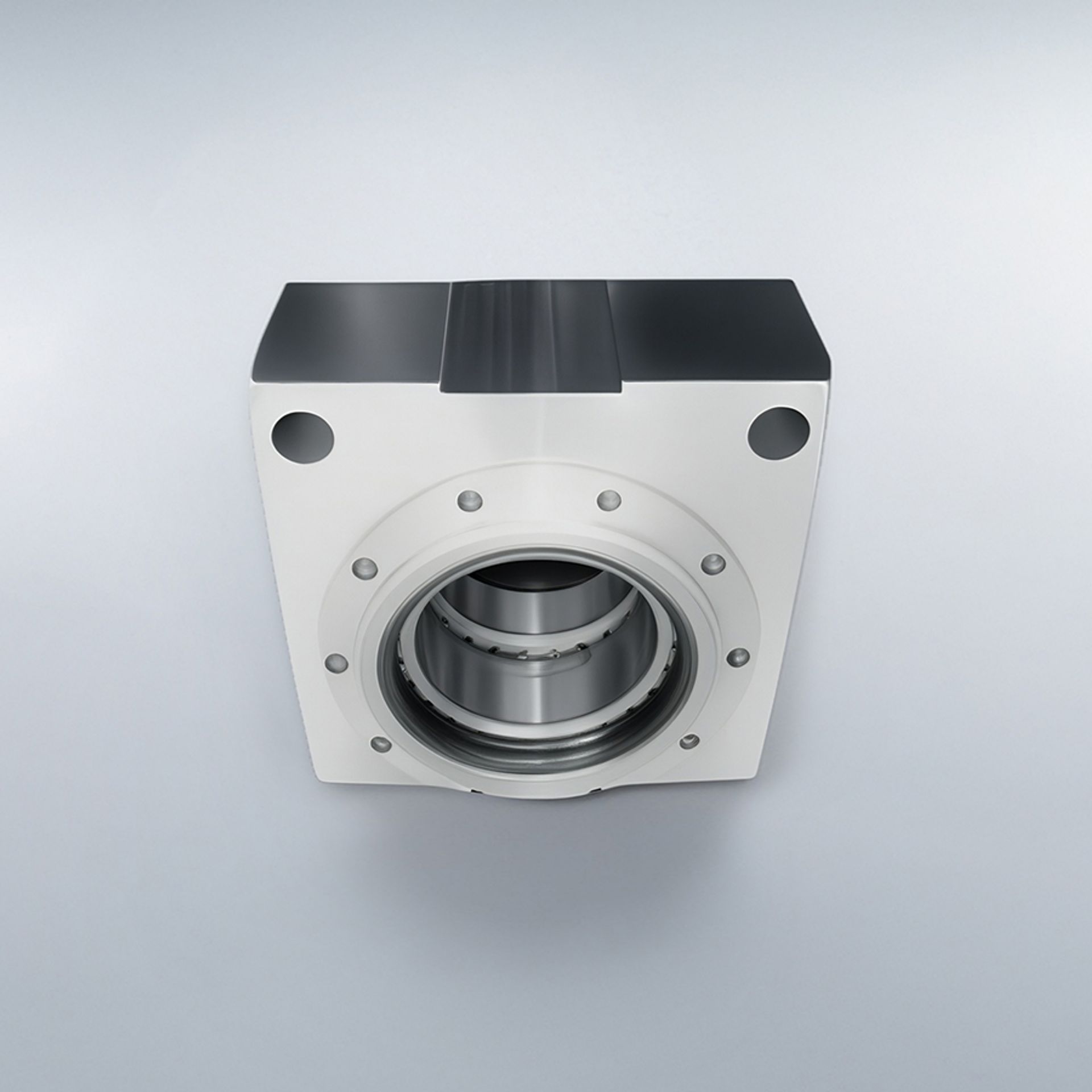

Engineering capability matters most at the start. Every facility is different. You have spatial constraints, power limitations, and equipment that must keep running during upgrades. Experienced manufacturers know how to integrate new systems with existing operations. They spot problems before they happen. Whether you need light section rolling mills or high-speed delivery rolling mills, the engineering must be right.

Manufacturing Quality and Support

Manufacturing quality determines how long your equipment lasts. Bar and section mills work under brutal conditions: high temperatures, heavy loads, continuous operation. Taiwan is recognized globally as a hub for steel industry engineering, combining rigorous quality standards with competitive costs.

Support infrastructure separates good manufacturers from equipment suppliers. Spare parts must be available when you need them. Technical expertise must be accessible. The best manufacturers offer flexible maintenance contracts, from periodic specialist help to comprehensive on-site programs.

Experience counts heavily. Manufacturers who have installed hundreds of systems have encountered problems that books do not cover. Darting’s 50-plus years means we have solved problems that newer manufacturers have never seen.

What Are Your Modernization Options?

”Upgrade or replace” is not an either-or choice anymore. Modern manufacturers offer many improvement options.

Targeted Upgrades and Phased Modernization

Some facilities need only targeted upgrades. Replace key stands while keeping surrounding infrastructure. You get significant quality improvements at lower cost than complete replacement. Darting offers rolling mill upgrades that enhance specific capabilities without complete system replacement.

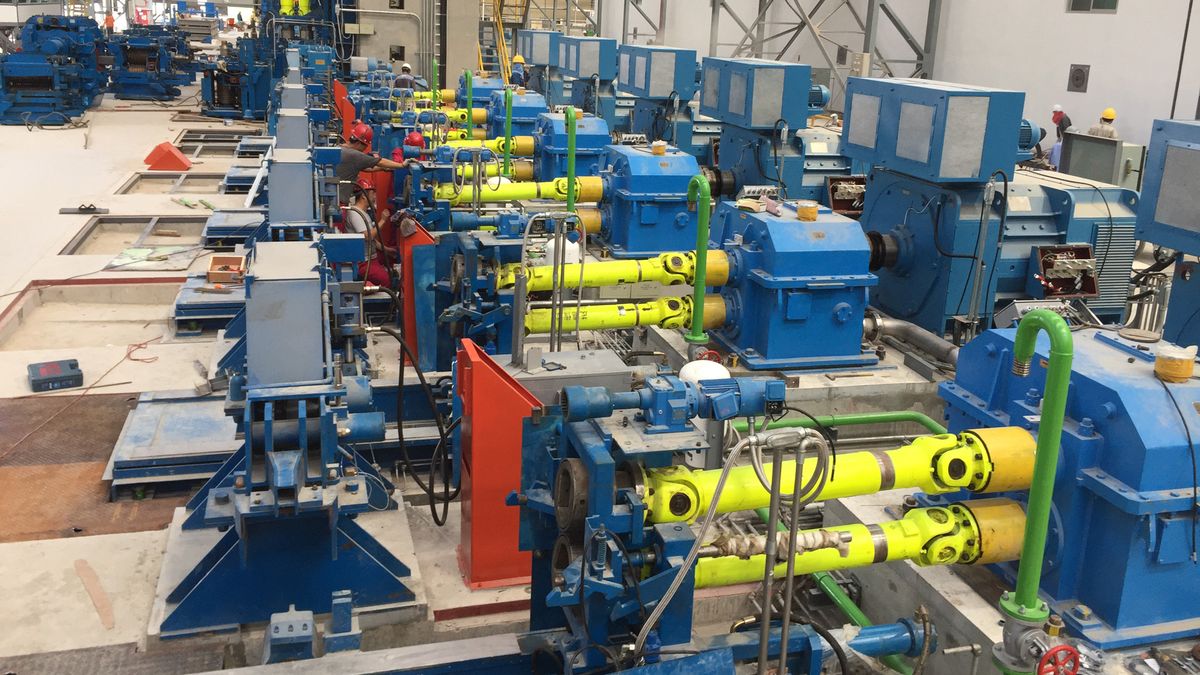

Phased modernization is another smart approach. Upgrade systematically over several years while keeping production running. Replace roughing mill components in year one, upgrade finishing stands in year two, add automation in year three. This spreads costs over time and makes cash flow manageable.

Bar and Section Mill - Complete New Installations

Some operations need complete new installations when existing infrastructure cannot support modern requirements. Complete installations let you design the ideal layout and integrate the latest technology throughout. Special bar quality rolling mills for precision applications or standard bar mills for high-volume production can be configured exactly to your specifications.

Darting specializes in taking existing space constraints and designing a whole new plant to meet your production needs without requiring plant expansion. Our systems will maximize your ROI and deliver an expanded range of products for your market.

Bar and Section Mill - Automation Levels

Mills come in three types: manual, semi-automatic, and fully automatic. Manual systems cost less initially and work well for operations with skilled operators. Semi-automatic systems balance cost and efficiency. Fully automatic systems maximize throughput but cost more. The right choice depends on your labor costs, production volume, quality standards, and budget. Most system installations are now semi or fully automatic with very few people required to monitor and maintain the system during operation.

Bar and Section Mill - Frequently Asked Questions

Can existing bar and section mills be upgraded without complete replacement?

Yes, most mills can be significantly improved through targeted upgrades. If the foundation, main structure, and drive systems are sound, you can upgrade specific components like mill stands, control systems, or delivery equipment. Access to quality rolling mill components makes these upgrades practical and economical.

What determines whether to upgrade or replace a rolling mill?

Equipment condition matters more than age. Consider structural integrity, production requirements, product specifications, and repair costs. Sometimes mills cannot be modified to meet new specifications. Other times, repeated repair costs exceed replacement cost. The best approach is thorough assessment by experienced engineers.

How long does mill modernization typically take?

Simple component upgrades might take weeks. Complete replacement can take 12-18 months from design to commissioning. Phased modernization extends over multiple years but maintains production throughout. Proper planning minimizes downtime.

What ongoing support should manufacturers provide?

Manufacturers should offer accessible technical expertise, readily available spare parts, and operator training. Critical components should be stocked for fast delivery. Flexible support options should range from specialist support to comprehensive on-site programs.

Why Choose Darting for Your Bar and Section Mill?

Choosing bar and section mill manufacturers determines what you can produce, how efficiently you operate, and whether you can compete effectively. The right partner brings engineering expertise, quality manufacturing, and ongoing support.

Darting has served the steel industry for over 50 years. We provide complete turnkey solutions from initial design through lifetime support.

- Fully automated bar & section mill lines

- Manual components & lines

- Semi-automated control systems

- Integration with existing automation & control systems

- ISO 9001: 2015 Certificate TA 2520-QC

We manufacture everything from rolling mill parts to complete wire rod and coil production lines. Whether you need targeted upgrades or complete new systems, we are committed to your success. Contact us today to discuss modernizing your rolling operation.