Why is Reverse Engineering of Rolling Mill Parts & Components Good For Business?

Operators of rolling mills have all encountered problems with the cost and availability of parts and components to keep their rolling mills running efficiently. A hidden cost of new machines, especially for European and Japanese brands, is how expensive replacement parts and upgrades can be. It is also surprisingly difficult sometimes to source parts for older equipment, especially if the original equipment manufacturer no longer manufactures or supplies parts.

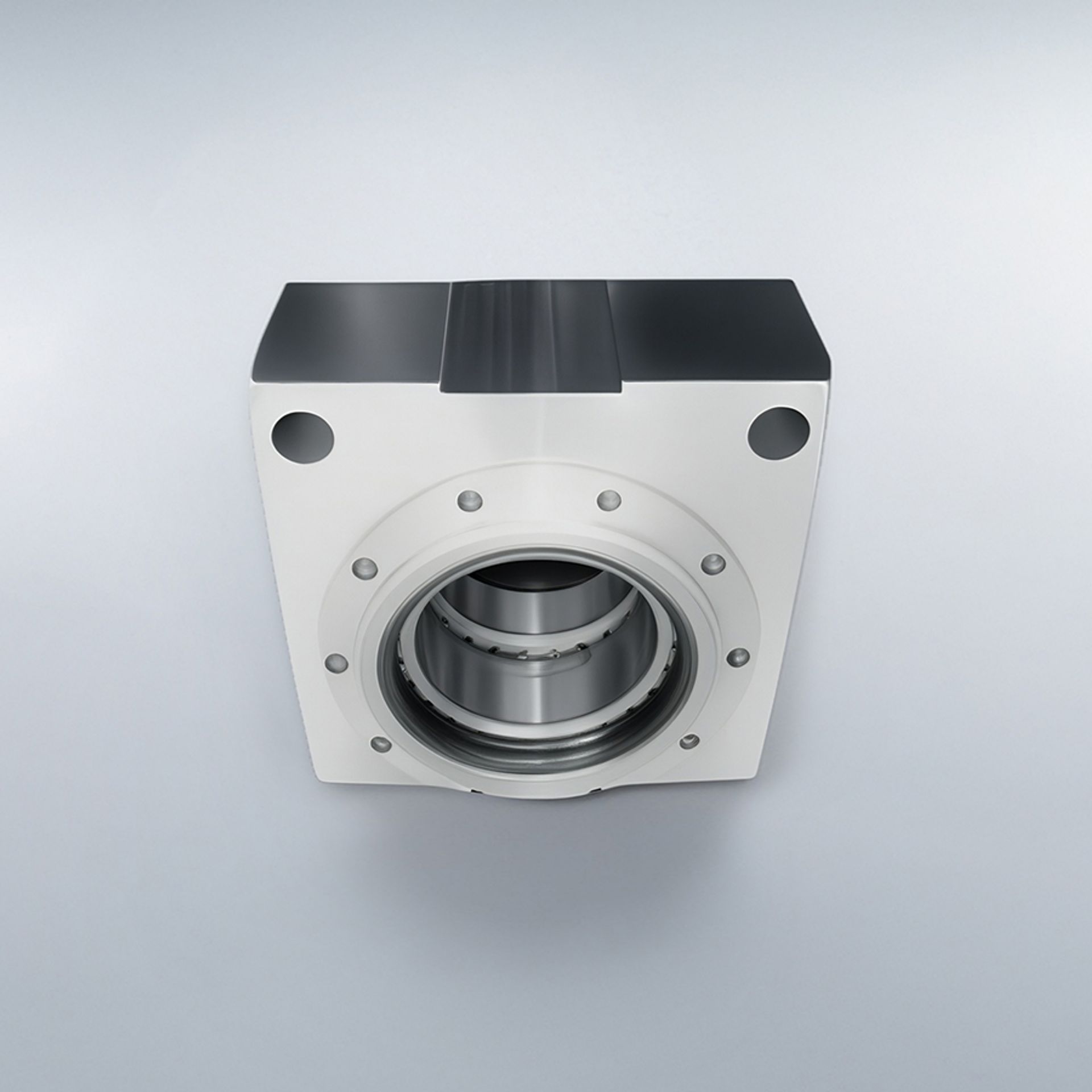

Darting has in-depth knowledge and extensive R&D experience in reverse engineering of production line parts and components for all types of industrial machinery. This means we can keep your existing lines working even when nobody makes parts for them any more or provide you with high quality alternatives to expensive European or Japanese parts and components. The best part is that with our excellent R&D we can usually make you a better part than the original, improving on the materials, manufacturing process or even the design to deliver a true win-win on price, and quality.