Rolling Mill Automation Explained: Manual, Semi-Automatic & Fully Digital Production Lines

Darting has been manufacturing durable and efficient rolling mill equipment for steel production lines worldwide for more than half a century.

Our global client list includes some of the biggest names in steel manufacturing, and we take great pride in applying our extensive expertise to assist smaller enterprises, growing businesses and new ventures.

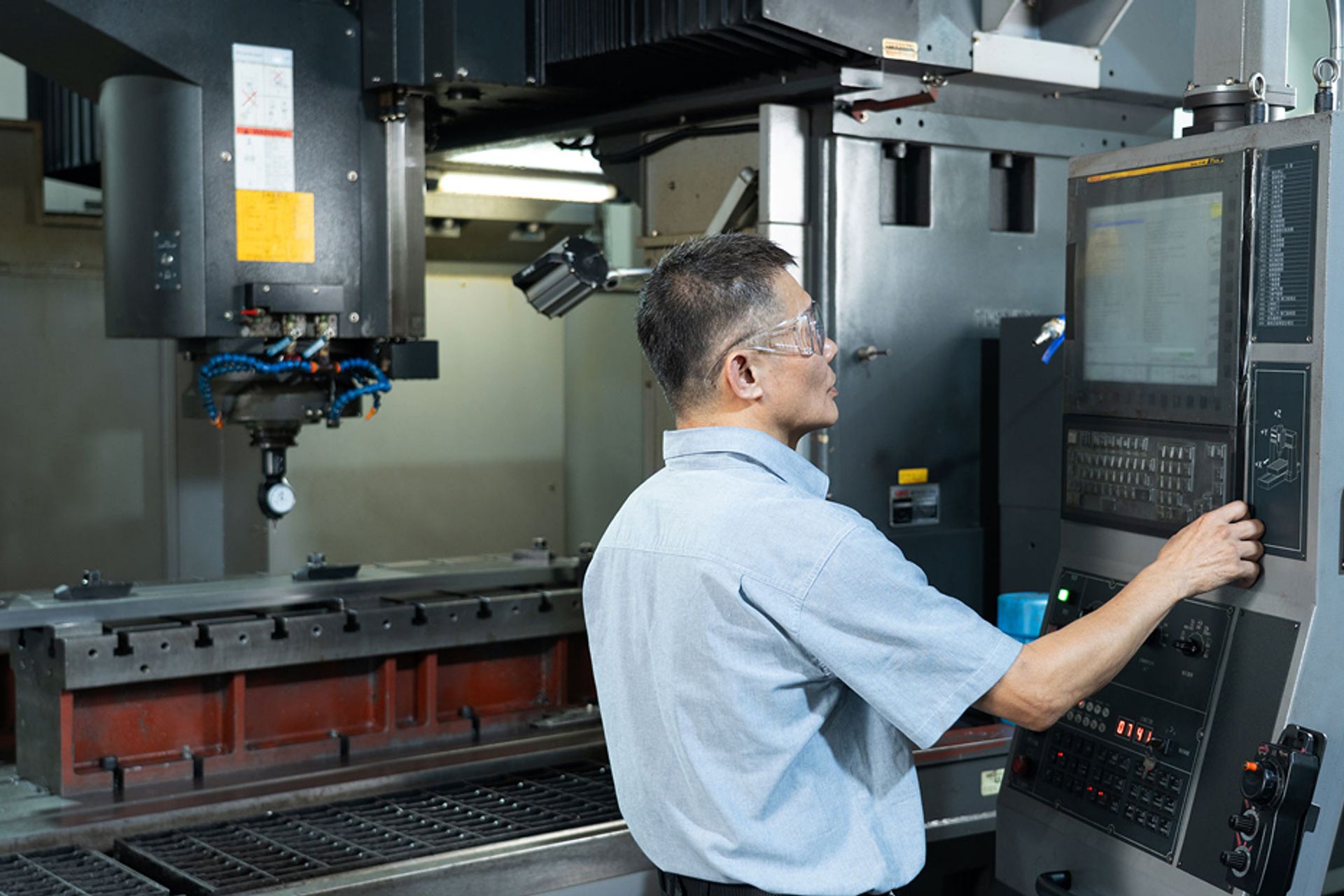

At our primary manufacturing facility in Taichung, we maintain a fully equipped workshop which combines state-of-the-art multi-axis precision CNC machining with a comprehensive suite of legacy technologies. This gives us the flexibility to deliver a comprehensive design, engineering and maintenance service for all types and sizes of manual, semi-automatic and fully automated steel rolling mills and components.

Inquire NowSince 1972 we have been building steel rolling mills and rolling mill components for both domestic and international partners.

Our client list includes some of the most recognizable success stories in manufacturing industries and steel production as well as an extensive customer base of manufacturers of a wide range of steel products from tire reinforcement to rebars.

Darting is based in Taichung City, Taiwan. This puts us in the heart of Taiwanese engineering and industry, with access to high quality materials and supply chain logistics that other rolling mill manufacturers can only dream of.

This means we can deliver the best steel rolling mill stands, components and equipment with extremely short lead times and respond rapidly to urgent maintenance and repair requests.

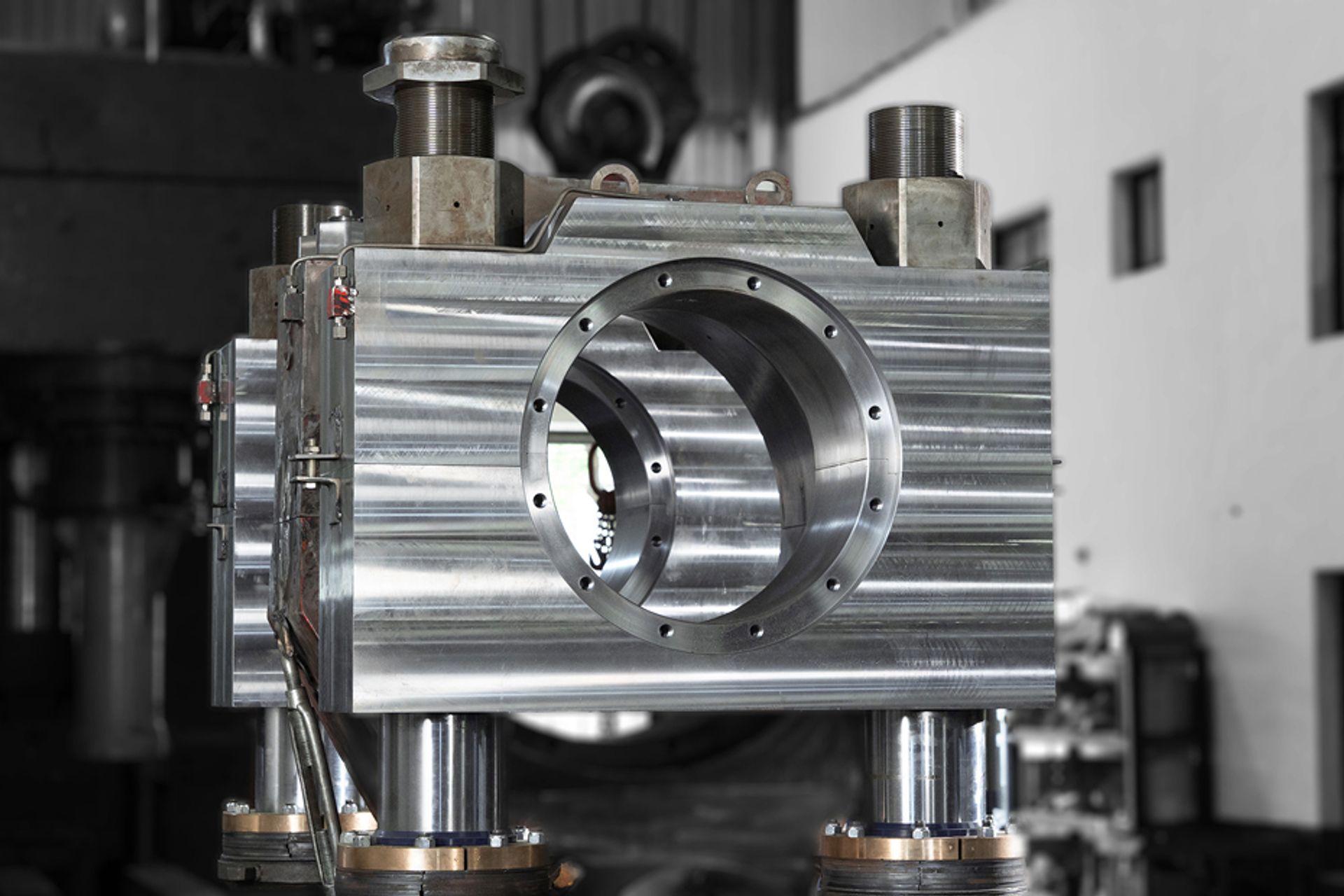

Our main business is in designing steel making plants and equipment and manufacturing steel rolling mill lines and line elements, including stands, calibers, crucibles and control systems. Darting provides durable and efficient rolling mill equipment for steel production lines worldwide. We can design and manufacture any type of steel rolling mill to any specification and scale.

This means we can deliver the best steel rolling mill stands, components and equipment with extremely short lead times and respond rapidly to urgent maintenance and repair requests.

See how our solutions have transformed steel production operations worldwide.

Another significant strength is our in-depth knowledge and capabilities in reverse engineering of production line parts and components for all types of industrial machinery.

We can keep your existing lines working even if the original equipment manufacturer no longer manufactures or supplies parts, or if the parts available are too expensive - which is a common problem with sourcing parts from Europe or Japan.

In the highly competitive steel manufacturing industry today, steel rolling mills can usually improve efficiency and profitability by upgrading production lines. Some upgrades are the result of improved material technologies that reduce wear, maintenance stoppages and overheads, others may come from increasing automation and improving energy efficiency.

Our extensive experience and embedded expertise enables us to find cost-effective, efficient upgrade solutions to extend the life of your existing steel rolling mill lines and improve your business performance. Sometimes all it takes is an expert investigation of your existing installation to discover simple ways to update and improve performance.

The design and engineering of efficient, optimized steel rolling mills is extremely demanding, requiring absolute precision and attention to detail in a high speed, hazardous industry. At Darting we apply the skills honed from our long experience in steel rolling mill manufacturing to design and engineer other types of industrial process lines, machinery and equipment.

The capabilities of the Darting team are the product of decades of skilled expertise in finding design solutions for many different processing industries. We are happy to work with you to develop the best engineering and manufacturing processes for your industrial needs within the constraints of your budget.