Rolling Mill Automation Explained: Manual, Semi-Automatic & Fully Digital Production Lines

We have 50 years of experience in R&D, design, engineering, installation, commissioning, and maintenance of all types of steel rolling mills. This gives us unique insights into the best methods, technology and approaches to use to upgrade your steel rolling mill. With our assistance you can improve efficiency to maintain competitiveness in the marketplace and modify your product portfolio to match new and emerging customer demand.

We support rolling mill operations worldwide, delivering reliable equipment and solutions with consistent quality and responsive service across every region.

Engineering and installation of rolling mill upgrades and parts requires expert skills and capabilities for trouble-free integration of new and upgraded components into the rolling mill line. There is no room for error when working with high speed steel rolling mills, and you need to feel completely confident in the reliability, safety and security of any modification, repair or upgrade. Our expert engineers apply their extensive experience to ensure you have no need to worry regardless of the scale of the project.

Successful steel rolling mills rely on R&D excellence to ensure efficient production, effective maintenance and seamless upgrades.

Because of the variety of installations and components used in steel rolling mills and the long history of rolling mill technology, it is a significant advantage to have the length and breadth of experience that the R&D team at Darting have built over the last 50 years. This means that whatever your problem or requirement, we can find the best, most efficient and cost effective solution for you.

Our R&D

See how our solutions have transformed steel production operations worldwide.

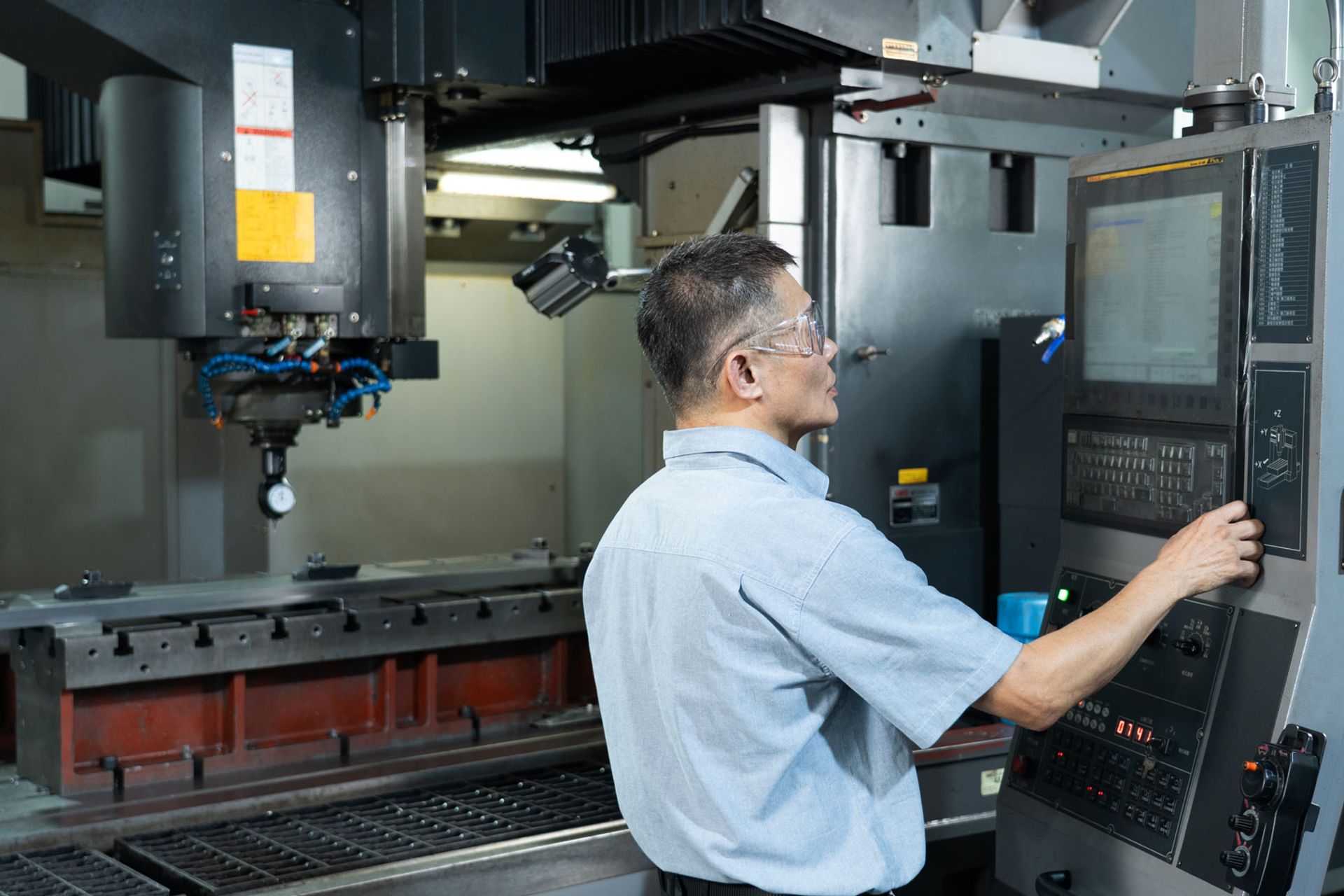

Rolling mills have automation and control systems that vary from sophisticated, fully automated complete lines to semi-automated and manual control systems.

Darting has the skills and experience to ensure that any rolling mill parts we supply will match your existing control system requirements. We are also highly proficient in designing and installing upgraded custom control systems as well as integrating individual components.

Darting provides ongoing support and upgrade options for all types of bar and section mill lines, including wire rod and coil components & accessories, maintenance and improvements for installations by other suppliers.

Contact us to see what savings and efficiency gains our experienced engineers can identify from upgrading your existing wire rod and coil manufacturing.

SupportWe're happy to answer any questions you have or provide you with an price quote . Just send us a message in the form below with any questions you may have.

Inquire Now