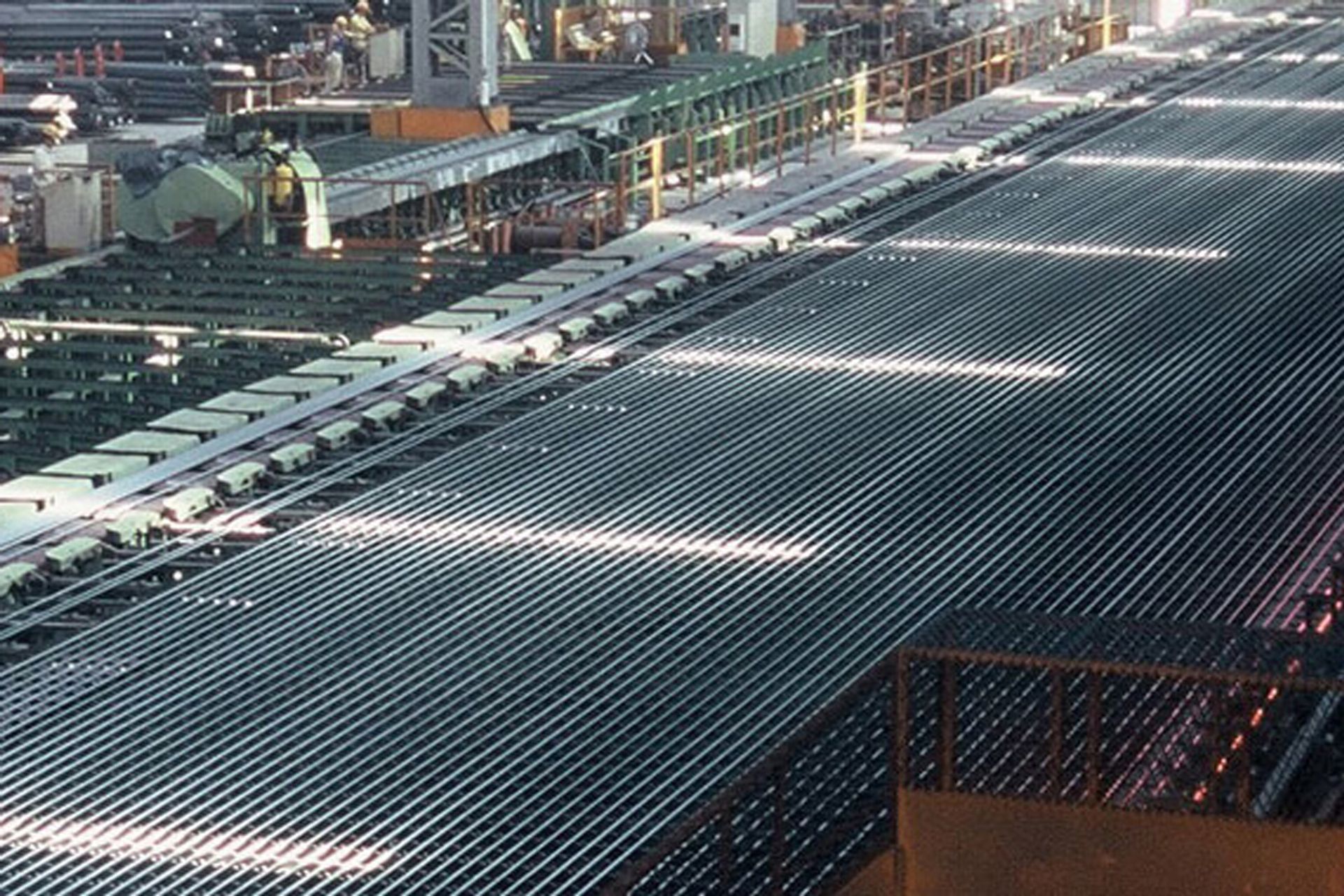

Rolling Mill Automation Explained: Manual, Semi-Automatic & Fully Digital Production Lines

Darting has been manufacturing durable and efficient rolling mill equipment for steel production lines worldwide for more than half a century.

We have 50 years of experience in R&D, design, engineering, installation, commissioning, upgrades and maintenance of all types of steel rolling mills.

Our insight and expertise maximizes the efficiency of your project and minimizes the financial and operational risk. Darting delivers rapid project turnaround, Taiwanese quality engineering, and customer-focused service to support our commitment to mutually beneficial long-term relationships with all our customers.

Inquire NowWhen you work with Darting you discover our flexibility, in-depth knowledge and friendly customer service. We know that no matter how big or small your project, there is always mutual benefit in getting the job done well, on time and within budget. From the very first time you speak to us you will discover how focused we are on delivering your project, responding to your needs, and adding value to your business.

The first step in the process when you work with us is to provide a list of products and the required capacity you need. We'll also need to know how much space you have available, and how much labour you want to employ. How many workers will be working on the production line will have a significant influence on how much automation needs to be included in the design, and this affects the cost. You will also have a budget in mind, which we will work through with you to develop the most efficient design.

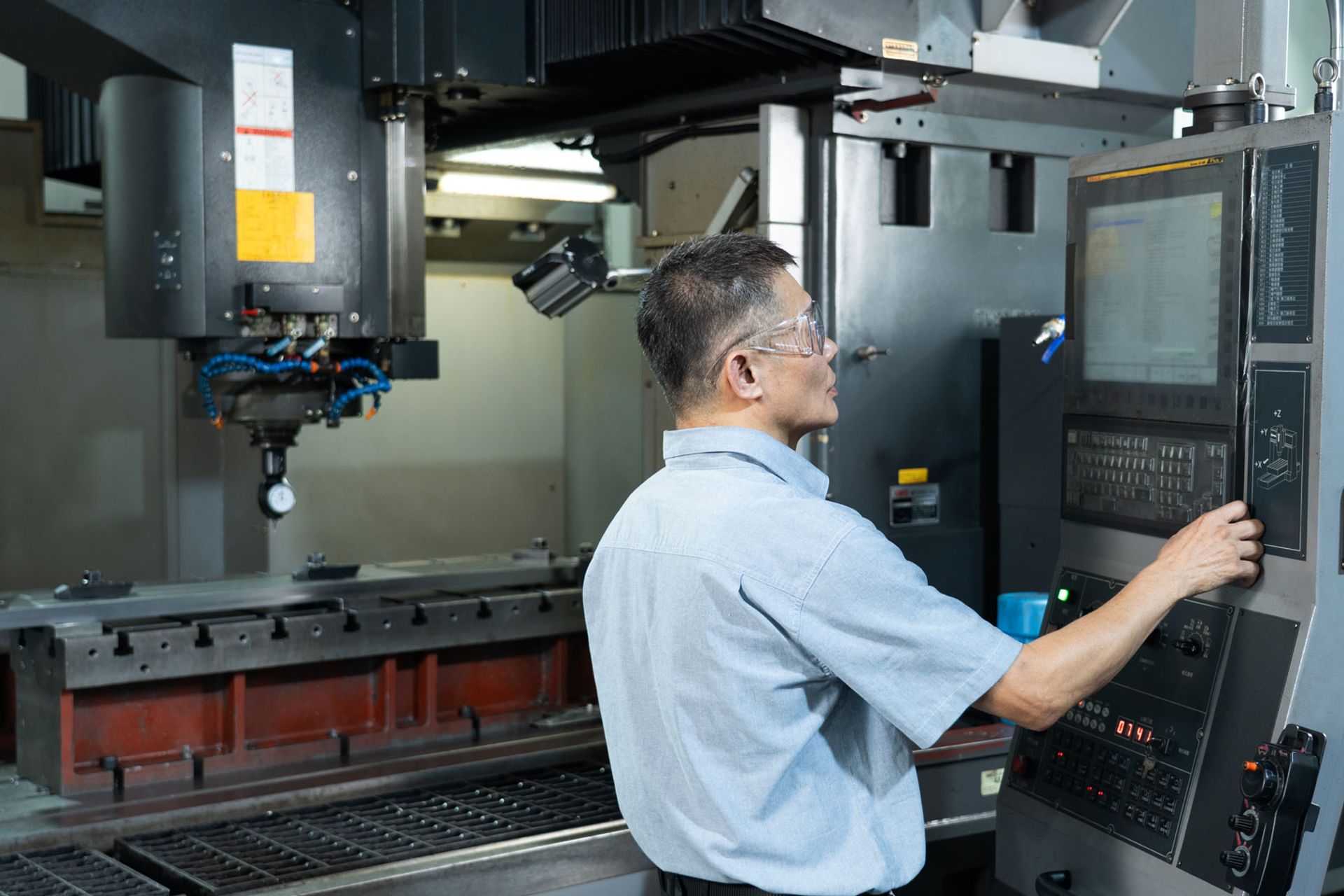

Our extensive experience and embedded expertise enables us to find cost-effective, efficient upgrade solutions to extend the life of your existing steel rolling mill lines and improve your business performance. Sometimes all it takes is an expert investigation of your existing installation to discover simple ways to update and improve performance.

Whether a customer asks us to build an entire mill, add a specific production line or improve a single process, there are four important parameters that are the starting point. Type of product, throughput capacity, space availability and the workforce size, or degree of automation required. We then design an appropriate process solution that fits within the available budget.

Our R&D

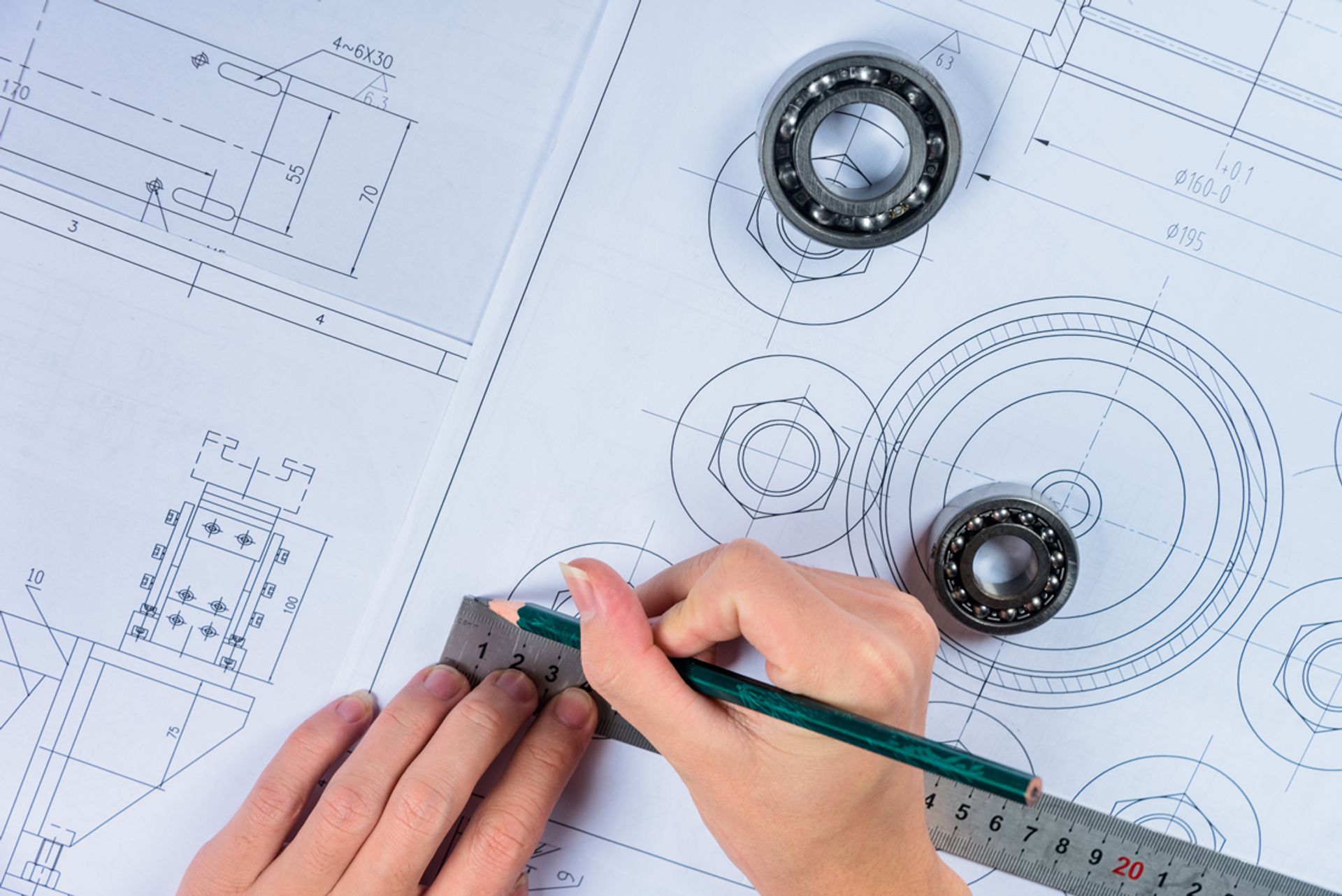

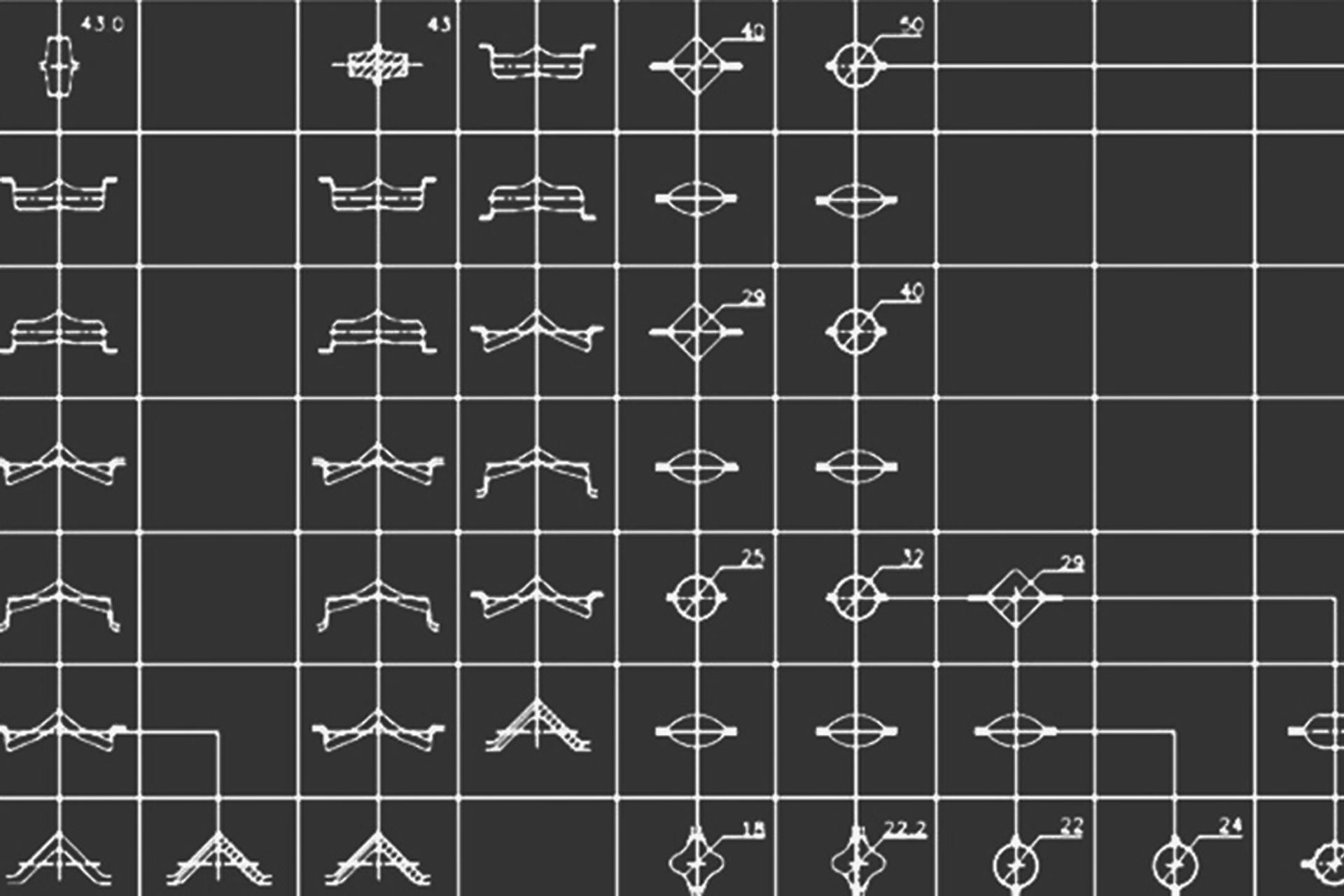

We make extensive use of computer modeled simulations of processes to get the design right first time, this is especially important for upgrades and efficiency improvements to steel rolling mills, where customers want to reduce the number of roll passes, change products or increase throughput speed.

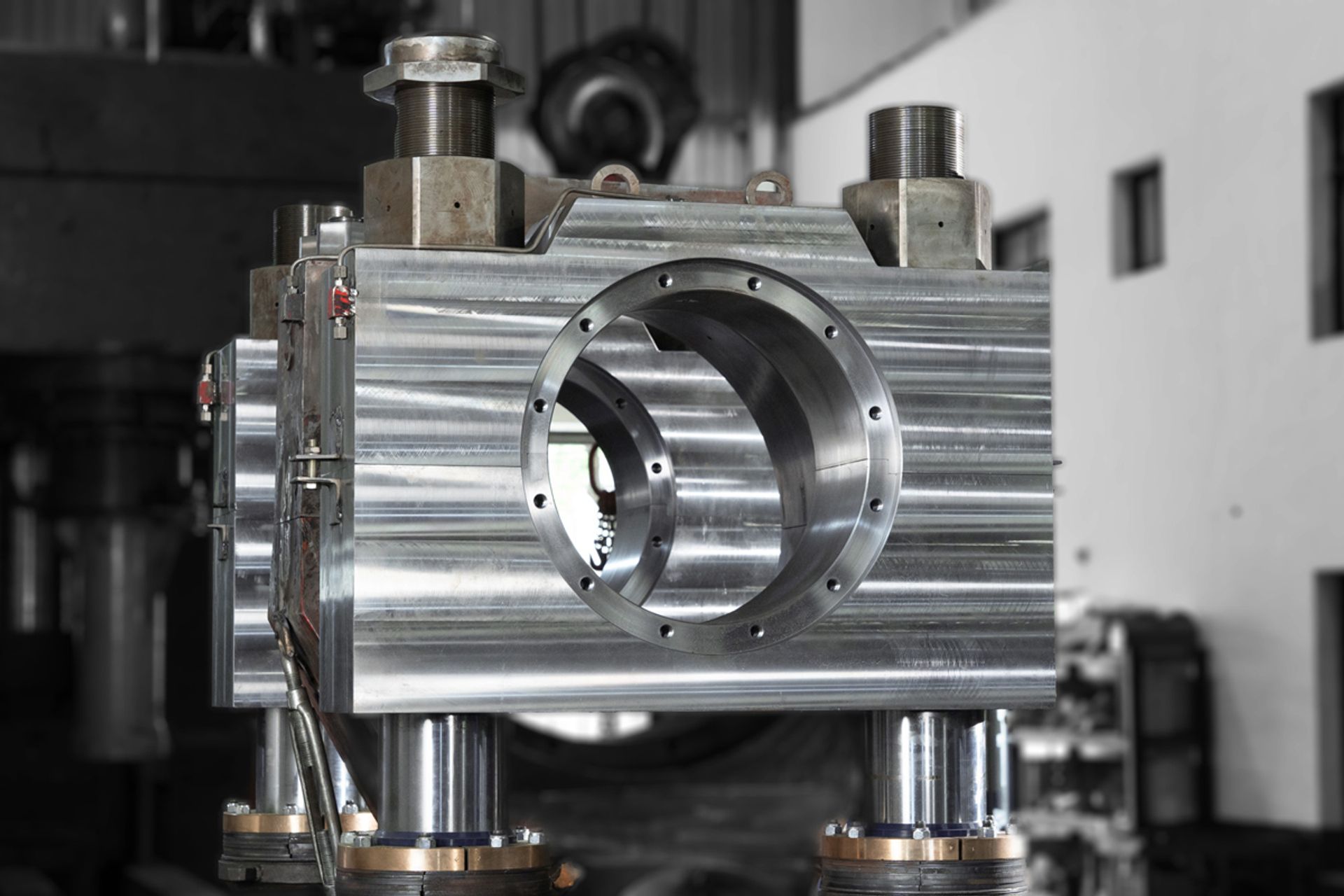

Our design engineers take your desired dimensions and specifications for the products you want to manufacture and we custom build lines with the machines to make each product type. For steel rolling mills, we can design, manufacture and supply different types of caliber which can be switched out on the mill stands to change the product.

In our experience, every customer has specific requirements, constraints or needs that have to be included in the design process, there’s no such thing as a ‘one size fits all’ steel rolling mill! With our extensive experience, this is where Darting provides a wealth of expertise and capabilities to ensure that your requirements are met and you get exactly what you want, on time, and within budget.

When you work with Darting you get rapid responses to your queries with intelligent, expert advice and support. Our research and design team are highly skilled professionals with a wealth of relevant expertise, and this, combined with our long experience of building successful projects for our clients, enables us to deliver on our promises of rapid turnaround and excellent quality.

Project development time from start to finish can be less than a third of what you might expect from a similar project delivered by a European mill manufacturer, and we guarantee that you will have a significantly better experience working with us than with our competitors. We prioritise excellence in design and delivery that leads to mutually beneficial long-term relationships with our customers.

From a new steel rolling mill project to a single hydraulic cylinder replacement, all our clients are valuable to us, and our success is based on long-term partnerships with our customers that create mutual benefits.

Our support, maintenance and upgrade services are as wide ranging as our rolling mill and industrial machinery capabilites. We can reverse engineer and supply improved spare parts to maintain or upgrade any brand or type of industrial machinery as well as our own product range.